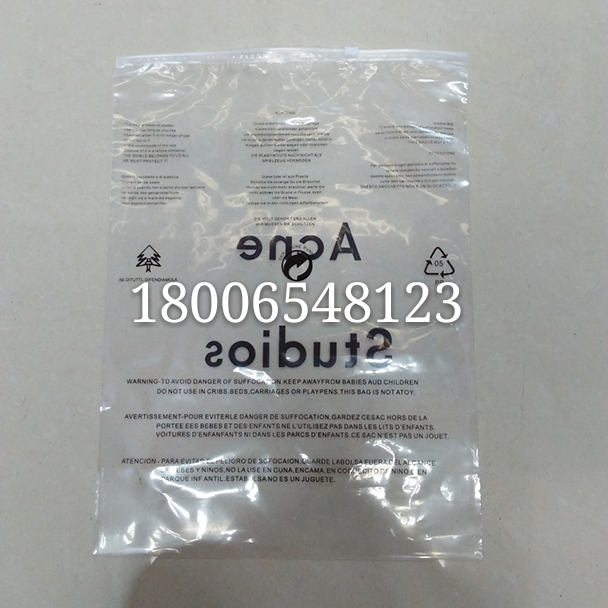

Looking for a unique packaging solution? Customized PE bags, PE zipper bags and PE hook bags provided by manufacturers meet the packaging needs of various products with their strong durability and flexible design. Whether it is storage or transportation, these high quality bags will bring you a new and convenient experience!

Understand the charm of PE material: why it is ideal for modern packaging

Polyethylene (PE) is an environmentally friendly and excellent plastic material. Because of its good flexibility and strong chemical resistance, it is favored in the field of modern packaging. Compared with traditional paper or other plastic products, PE materials are not only lighter and stronger, but also have excellent waterproof performance and can remain intact in humid environments.

From basic to high-end: in-depth discussion on the diversified application scenarios of customized PE bags

Whether in the food industry, electronic product protection or commodity packaging, custom PE bags can play an important role. For example, the PE zipper bag with sealing strip design is very suitable for storing snacks, biscuits and other damp-prone items. The thickened PE hook bag can be hung on the wall to organize clothes accessories and other objects, greatly saving space and increasing aesthetics.

How to make your brand stand out through personalized design-the unique advantages of PE bags

In addition to powerful functionality, customization is also a highlight of PE bags. You can freely adjust the color matching, printing pattern and even special shape cutting according to the image requirements of your own enterprise to create a unique product appearance style. This will not only deepen the customer's impression of corporate brand recognition, but also stimulate consumers' desire to buy.

Quality First: Understanding the Control of Durability and Safety in Manufacturing

In order to ensure that every PE bag delivered to customers is the best choice, we use advanced production equipment and technical means to monitor the production process throughout. From the beginning of raw material screening until the finished product inspection before leaving the factory, it must go through strict testing to ensure that all indicators reach the international standard level.

Success Story Analysis: See How Other Companies Benefit from Customized Packaging Solutions

A well-known cosmetics company once faced the problem of high product packaging breakage rate. After trying to replace it with our custom PE bag, it found that the situation has been significantly improved. As the newly selected material is more tough and firm, coupled with reasonable size planning, the leakage of contents due to extrusion will never occur during logistics and distribution, and finally won the trust and praise of more users.