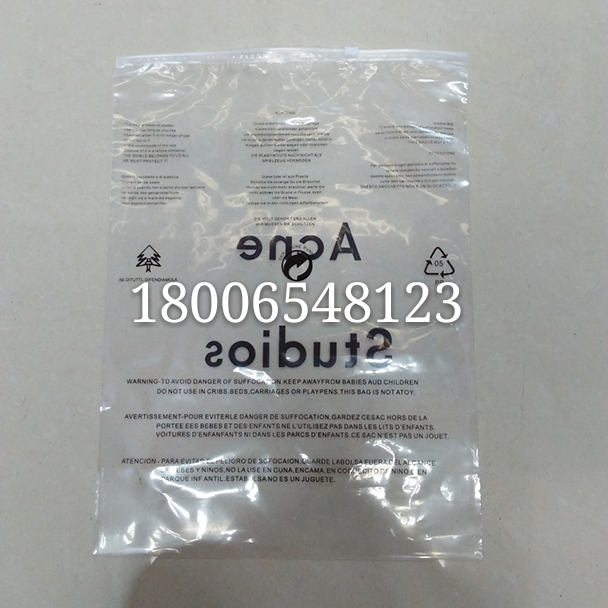

Custom PE Bags – Zipper & Hook Closure Solutions for Secure Packaging

Imagine a customer walking down a crowded retail aisle. Shelves overflow with similar products, yet one package stands out—not because of flashy graphics alone, but because it feels intentional. The moment they pick it up, the texture, the closure, the clarity of the material—all whisper quality. This is the silent language of packaging, and in today’s competitive market, your brand can’t afford to stay quiet.

Packaging’s Silent Storytelling: How a Simple Bag Builds Brand Identity

Packaging is often the first physical interaction a consumer has with your product. It shapes perception before a single feature is experienced. A well-designed custom PE bag does more than protect—it communicates care, consistency, and credibility. When you customize the size, color, logo, and closure type, you transform a functional item into an extension of your brand identity. From shelf appeal to unboxing experience, every detail contributes to trust and recognition. Whether used in B2B shipments or direct-to-consumer kits, these bags silently reinforce professionalism at every touchpoint.

Beyond Sealing: The Engineering Behind Zipper & Hook Closures

Not all closures are created equal. The innovation behind PE zipper bags lies in their ability to maintain a tight seal through repeated openings—ideal for products that require frequent access without compromising integrity. The interlocking profile ensures dust, moisture, and contaminants stay out, while preserving freshness and cleanliness. On the other hand, PE hook closure bags offer superior strength and ease-of-use for heavy-duty applications. Their snap-fit mechanism provides instant sealing with high tensile resistance, making them perfect for industrial components or bulky retail items. Both systems leverage advanced material science—combining optimal PE thickness with structural resilience to deliver performance where it matters most.

Solving Real-World Challenges Across Industries

In retail, precision matters. Think of small electronics accessories, garment labels, or jewelry inserts—items easily lost or damaged without proper containment. Custom PE zipper bags keep these components organized, visible, and protected. In industrial settings, the story shifts toward durability. One manufacturer reduced part damage by 40% simply by switching to reinforced PE hook bags for internal transport. Even in food-adjacent applications—where direct contact isn't required—these bags meet hygiene standards by acting as secondary protective layers, ensuring compliance with safety protocols during storage and transit.

Customization: Efficiency Disguised as Flexibility

True customization isn’t about luxury—it’s about alignment. By tailoring dimensions, adding branded printing, selecting colors that match your packaging line, or integrating handles for convenience, you streamline operations across fulfillment and logistics. Need a narrow bag for headphone packaging? Or a wide, tall version for toolkits? With flexible die-cutting and rapid sampling support, manufacturers can adapt quickly. This reduces excess material usage, minimizes void fill, and optimizes shipping volume—cutting costs and environmental impact simultaneously.

The Advantage of Going Direct: Manufacturer-to-Business Value

When you source directly from a manufacturer, transparency becomes your ally. Without middlemen inflating prices or slowing communication, you gain cost efficiency and agility. Changes in design, urgent reorders, or unexpected demand spikes can be addressed swiftly. More importantly, long-term partnerships ensure consistent material quality, batch after batch—critical for brands building reputation on reliability. This direct link also fosters innovation, as technical teams collaborate to refine performance based on real-world feedback.

Durability as Sustainability: Rethinking Waste Through Design

Sustainability isn’t just about recyclability—it’s about longevity. High-strength PE resins allow these bags to endure multiple uses without tearing or degrading. Fewer replacements mean less waste, lower carbon footprint, and stronger ESG reporting. These bags are fully recyclable where facilities exist, aligning with global trends toward circular economies. By choosing robust over disposable, companies embrace a “less is more” philosophy that benefits both planet and profit.

Where Function Meets Aesthetics: Packaging That Performs and Impresses

Why choose between practical and polished? Modern printing techniques allow for vibrant, precise branding—even on translucent PE films. Combine a transparent viewing window with bold color blocks and crisp logos to create instant shelf distinction. For B2B clients, this signals professionalism; for end consumers, it elevates perceived value. The result is packaging that protects, informs, and impresses—all in one seamless design.

The Next Big Idea Might Start With a Small Change

Breakthroughs often begin quietly. Maybe your current packaging leaks air, lacks visibility, or fails under stress. Instead of accepting it, consider a trial run—a “test generation” of custom PE bags with improved closure or sizing. Small-batch prototyping lets you validate improvements before scaling. And looking ahead, these platforms can evolve: imagine integrating scannable QR codes, anti-tamper indicators, or even smart labels for inventory tracking. The future of packaging isn’t just secure—it’s intelligent.

Your brand deserves packaging that works as hard as you do. With custom PE bags featuring zipper and hook closures, security, sustainability, and style aren’t trade-offs—they’re guaranteed.